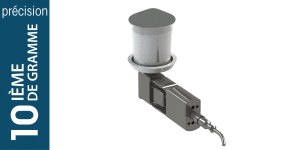

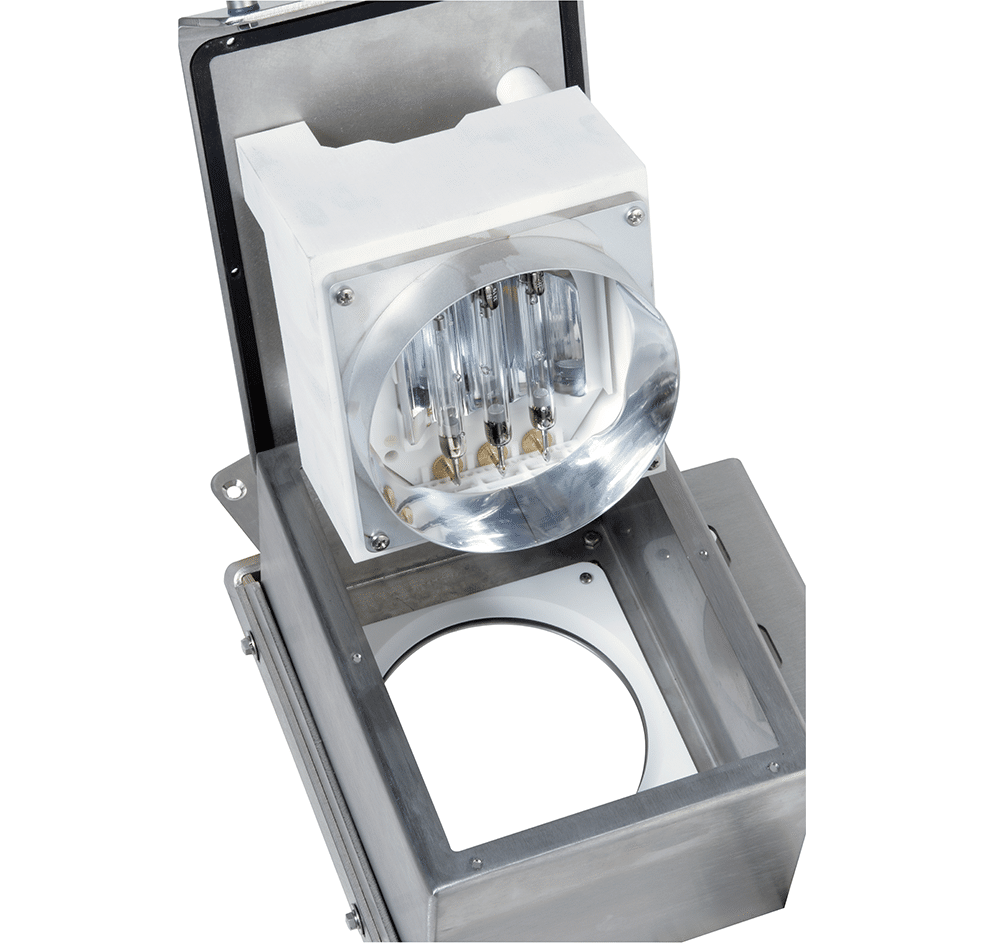

LPURE decontamination module

a powerful, compact decontamination module

Professionals in the agri-food industry must ensure that their products are perfect hygiene in their packaging process. In the interests of eco-responsibility, and as part of their CSR policy, they are increasingly opting for clean decontamination, without chemicals or effluents, such as pulsed light decontamination modules.

Packaging machines, which are increasingly efficient and compact, must also meet growing requirements in terms of food safety, with ever tighter budgets.

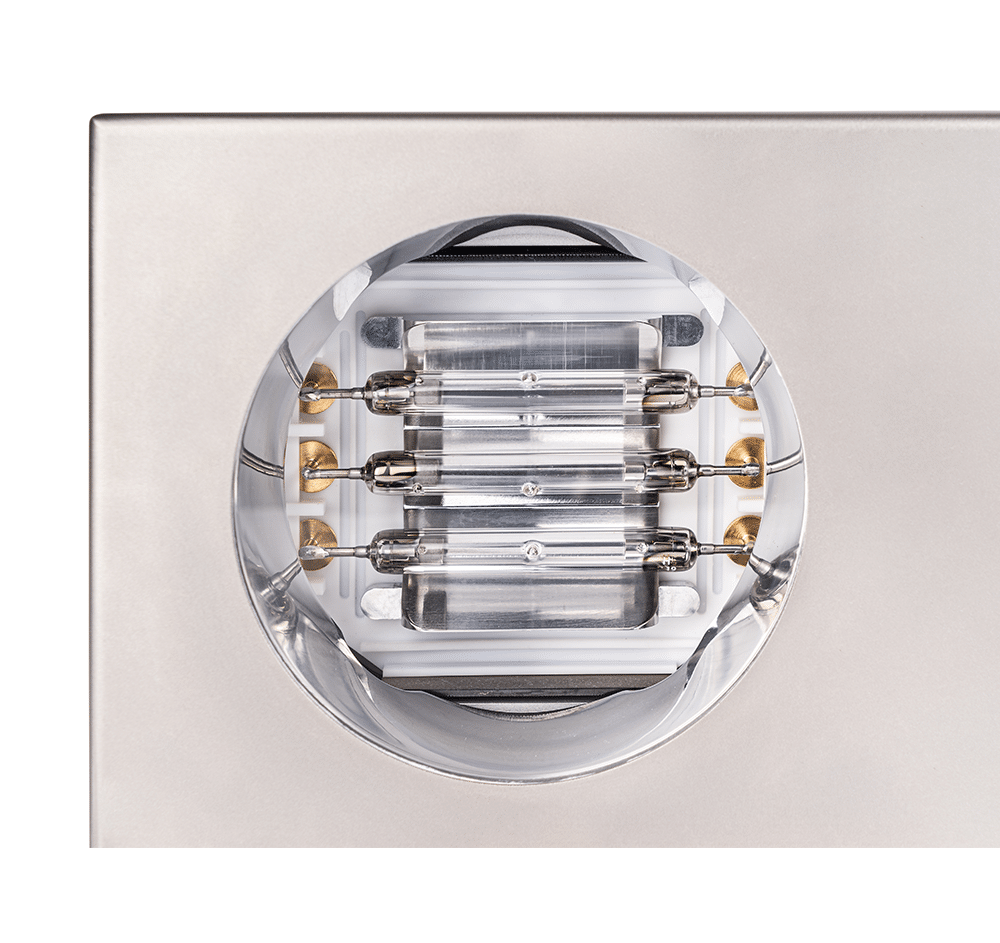

LPure is a a high-performance, eco-responsible & economical pulsed light decontamination solution, perfectly suited to all PACKINOV packaging machine ranges and all types of production.

Up to

more economical

Up to

in just 1 flash

- reliability

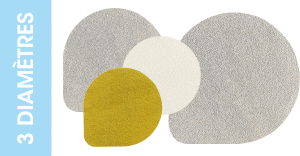

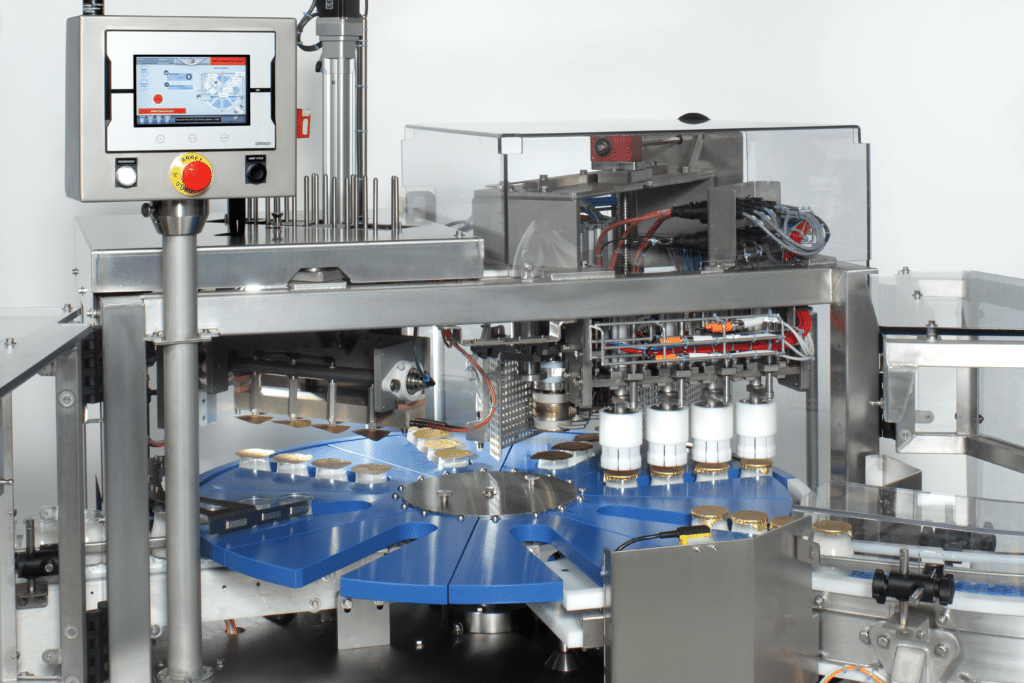

Highly efficient and effective, the LPURE decontamination module makes your production more reliable, both in single and multi-track mode, guaranteeing you perfect decontamination of the pot and lid, with 3 to 6 batches in a single flash.

- eco-responsible

With use chemical-free, mercury-free and water-freeThe LPURE decontamination module is part of a genuine eco-responsible approachThis avoids dangerous storage and the risk of explosion.

- economic

With a low acquisition cost, the LPURE decontamination module meets the budgetary requirements of everyone, industrialists and craftsmen alike. The cost of consumables is also reduced, which making it a highly economical decontamination module.

Its price positioning makes it accessible to all.

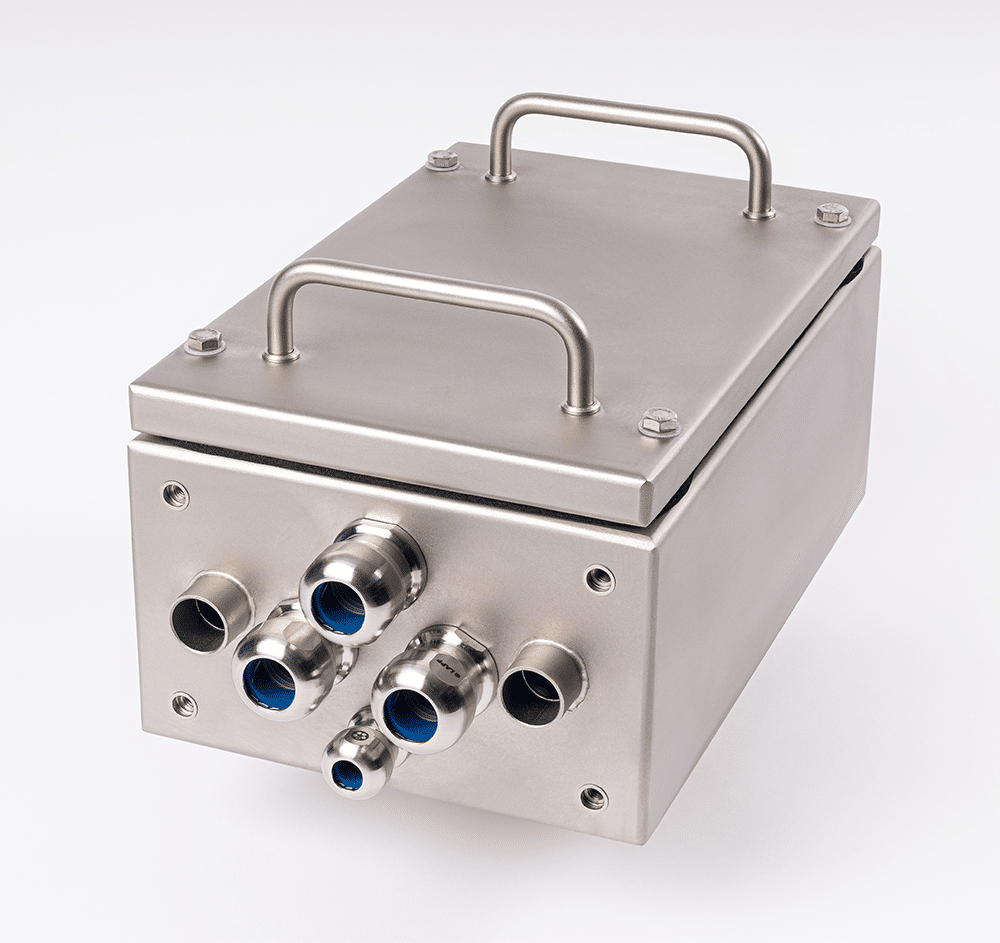

- compact

Both the optical head and the electrical block are reduced in size for reduce the footprint of the decontamination module.

It fits in with all packaging machines linear or rotary, new or in retrofiteven the most compact.

The electrical unit can be integrated on or under the equipment.

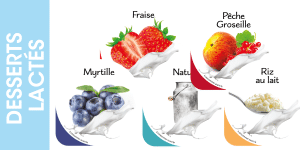

ADAPTED TO YOUR PRODUCTS

Cottage cheese

Fresh cream

Yoghurts

COMPOST

grout

fruit puree

jam

milk

sauces

mayonnaise

ketchup

SPICES

TEAS

SEL

CONDIMENTS

Manufacture

100% French

Since 1997, PACKINOV designs and manufactures rotary machines and automatic packaging lines adapted to all products in rigid containers in Beynost (01).

From the outset, this company has opted for the 100% MADE IN FRANCE.

Innovative, top-of-the-range French manufacturer, PACKINOV is present in France and abroad and supports its customers at every stage of their project, in a spirit of partnership. global packaging solution with machines but also pots, the lids and many associated services.

Compact

To try it is to adopt it

economic

eco-responsible

LPURE, an economical and compact solution

Designed for installation

INTEGRATED

on an existing machine

IN RETROFIT

to replace an existing solution

ON A NEW MACHINE

for end users or machine builders

LPURE, a collaborative innovation between PACKINOV and PHOXENE,

manufacturer of flash solutions.

The benefits of the LPURE decontamination module

- Compact

- Economical

- Reduces consumables costs

- Acquisition cost 2 to 3 times lower

- Can be integrated into new machines or retrofitted

- Suitable for both linear and rotary machines

- Limited space

- Stainless steel

- Very easy to clean: CIP

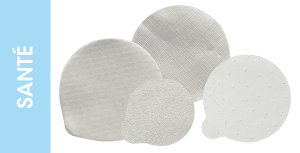

- Complete decontamination of jar and lid

- No chemicals, mercury or water

- Very easy to use

Discover the LPURE decontamination module

Reading list

LPURE decontamination module suitable for :

PACKINOV's LPURE decontamination module is very compact and fits perfectly on both rotary and linear machines.

TO THE LPURE DECONTAMINATION MODULE

After-sales services

PACKINOV's after-sales service is at your side to maintain, repair and upgrade your machine, filler or dispenser.

You can also consult our after-sales guides for routine maintenance of your machine.

FUNDING ASSISTANCE

PACKINOV can help you with the administrative procedures involved in financing your machine.

Our machines are eligible for AGILOR, AGRILISMAT and ACTIMAT financing, and can be leased.

MADE-TO-MEASURE DESIGN

Discover the know-how and expertise of our teams by entrusting them with your project for tailor-made developments.

Maintenance

PACKINOV's teams carry out annual maintenance on your machine and replace wearing parts to ensure that your filling machine operates at optimum efficiency and that your production continues uninterrupted.

Manufacture

100% French

All our machines are developed and manufactured in France.

Discover our production site in pictures.

They trust us