The excellence of Corsican cheese with respect for the land and the animals

In the heart of the Figari plain, in the south of Corsica, nestles a farm like no other: the Fromagerie Valicella. Set up in 2000, this family-run, traditional, organic business has built up a solid reputation thanks to its commitment to production that respects the land and the animals.

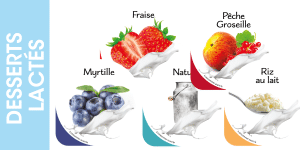

From cheeses such as Tomme Sartenaise and Brocciu to olive oil and yoghurts, everything is made on site. The yoghurts come in 440ml glass jars, a family size that encourages recycling thanks to a deposit system. More recently, the company has expanded its range to include traditional-sized yoghurts in cardboard pots, in line with its eco-responsible approach.

Quality is the watchword at Fromagerie Valicella. Each product is carefully crafted, from rearing to distribution. The farm is home to a flock of 450 Corsican ewes, all organically reared. Their well-being is a key concern for the company, which strives to work as naturally as possible.

Our ecological footprint is a priority," says Thomas Marcellesi. By favouring local sales, particularly in the Porto Vecchio region and southern Corsica, Valicella is helping to reduce its environmental impact. A small quantity of products is also sent to the mainland, enabling more gourmets to discover the authentic flavours of Corsica.

Fromagerie Valicella is much more than just a company: it's a passionate family who, every day, do their utmost to produce exceptional cheeses and yoghurts, with respect for tradition and nature.

a farm like no other

Our ecological footprint is a priority," says Thomas Marcellesi.

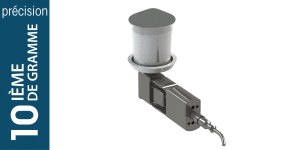

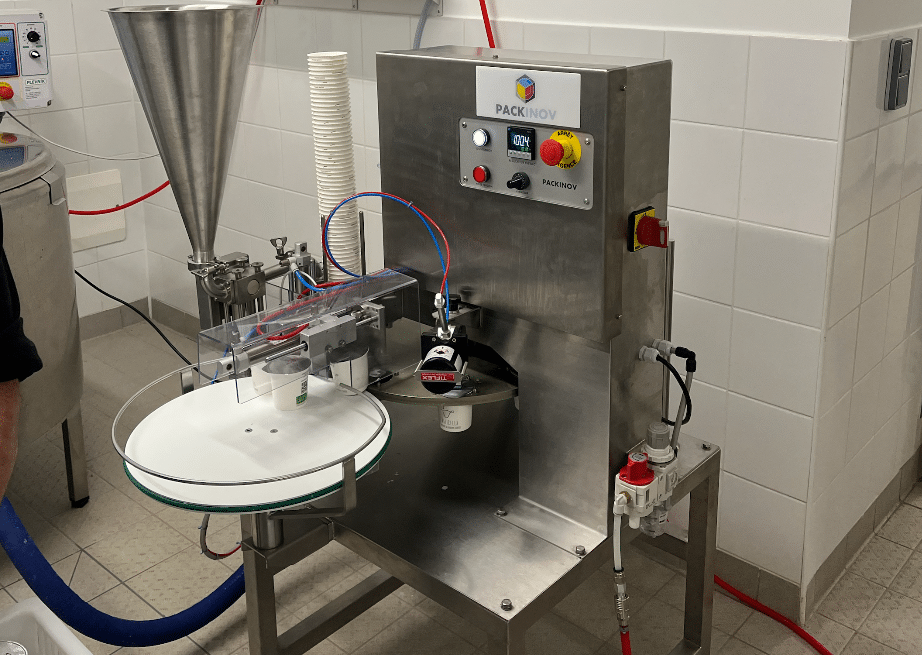

PACKINOV yoghurt filling machine to speed up production and diversify formats

Fromagerie Valicella recently reached a new milestone. The family-run business has acquired a PACKINOV yoghurt filling machine, a piece of equipment that will enable it to increase production and expand its product range.

For Mr Marcellesi, this decision reflects a desire to expand his range and adapt his products to the needs of all consumers, young and old alike. By introducing traditional-sized yoghurt pots into their range, the company is looking to achieve wider distribution, particularly in small and medium-sized retailers.

This PACKINOV yoghurt filling machine also enables the dairy to automate its production by increasing the number of yoghurts made, while freeing up time to concentrate on other aspects of the business.

Valicella's commitment to organic production and eco-responsible packaging remains unchanged. Respect for the land and animals is at the heart of their approach, with farming that avoids deep tillage, ploughing and the use of chemical inputs.

its satisfaction following the purchase of its PACKINOV yoghurt filling machine

"It's a machine that I felt was perfectly suited to my needs and efficient," says the owner of the cheese dairy. Compact and perfectly suited to the size of their operation, the PACKINOV yoghurt filling machine offers the right balance between a small-scale machine and an overly industrial and expensive solution.

"The discussions with the PACKINOV team were very positive," he adds. "We were supported throughout the process of purchasing and getting the machine up and running, which made the transition much easier."

Today, the machine is working well. Production volumes are set to increase gradually. The owner of the cheese dairy is satisfied with his investment: "I've got the machine under control.

Getting the machine up and running was made easier by remote assistance from the PACKINOV team. Clear and precise explanatory videos enabled the Valicella team to quickly understand how the machine worked. "During the first production run, we had a few questions and the PACKINOV team was very responsive in helping us," says the owner.

The purchase of this yoghurt filling machine was supported by a European grant, an invaluable support for the cheese dairy.

With this new acquisition, Fromagerie Valicella confirms its commitment to producing organic, high-quality, eco-responsible yoghurts, while looking to the future and innovation.

100% French design and manufacture

All our semi-automatic and automatic machines are designed and manufactured in France by our in-house Design Office, at our production site in Beynost in the Ain department, in the heart of the Auvergne-Rhône-Alpes region. More than just a sales argument, at PACKINOV, 100% French manufacturing is a reality and almost an obsession!

And our objectives are clear: to reach 100% of PACKINOV subcontracting partners in France, so that we can play an active role in the national revival and momentum.

Today, our results are already very positive, with over 98% from our partners based in France, including 73% in the Auvergne Rhône Alpes region and 19% in the Ain. And the others are all European!

They trust us