COSMETICS INDUSTRIES

precise, reliable and high-performance

The cosmetics industry is a key sector of the French economy, growing year on year to reach more than 76 billion euros in sales in 2020 in Europe alone. With more than 15,000 billion euros of cosmetic products manufactured in France by 2022, the France is the world's seventh largest producer and second in Europe after Germany.

The cosmetics industry is subject to stringent regulatory requirements, in particular with regard to packaging and hygiene, requiring the use of reliable, high-performance, modular packaging machines to keep up with customer trends.

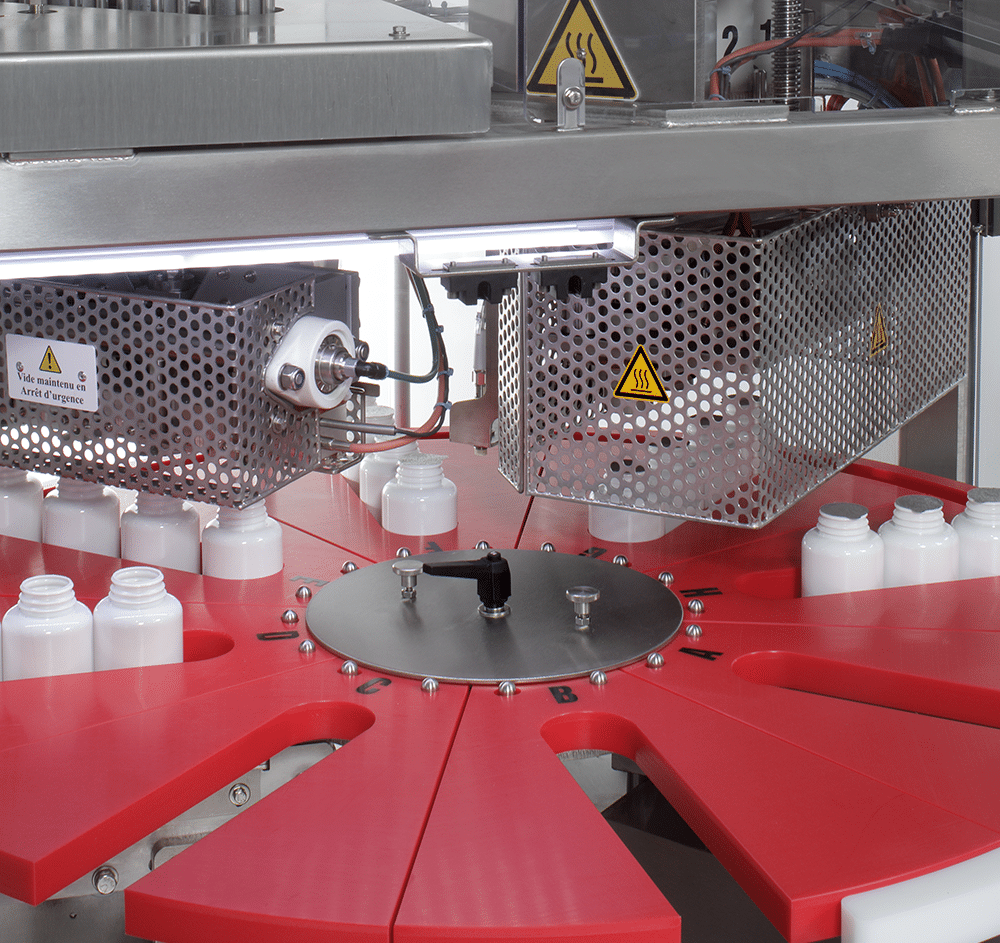

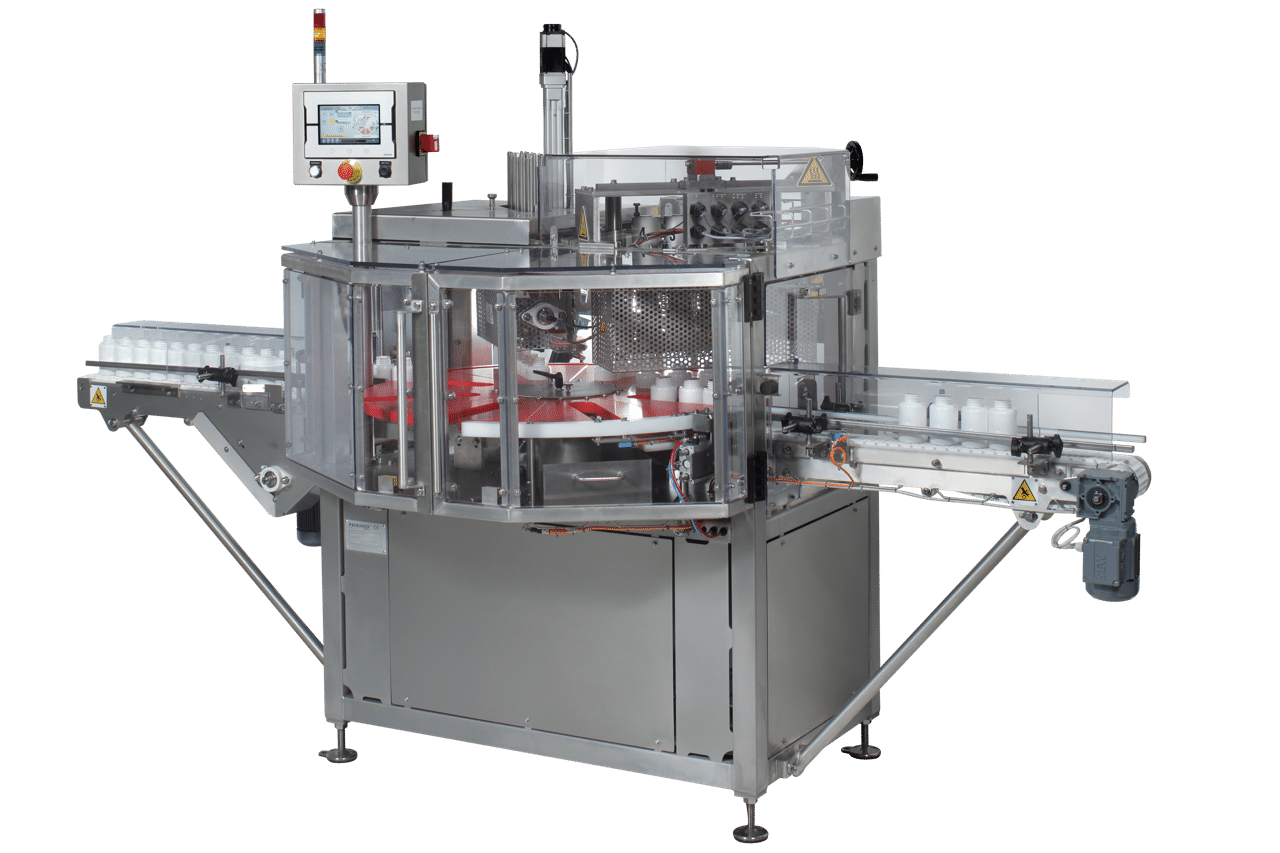

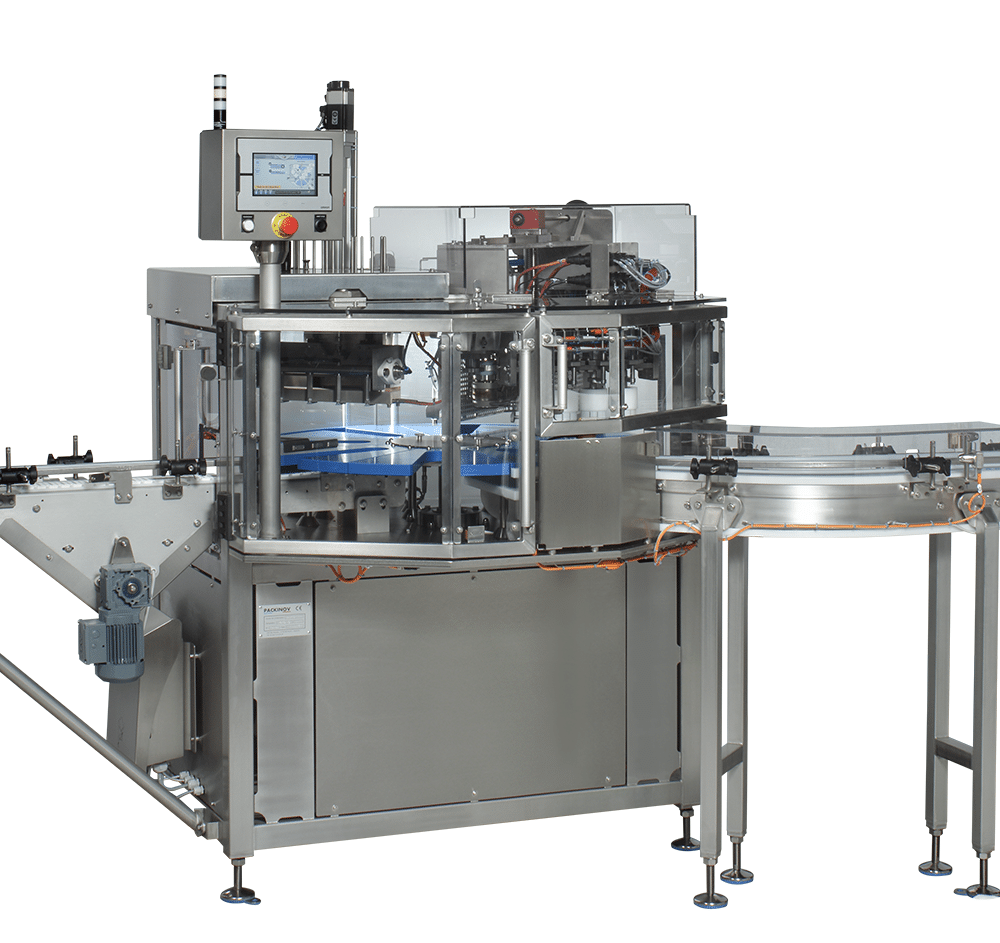

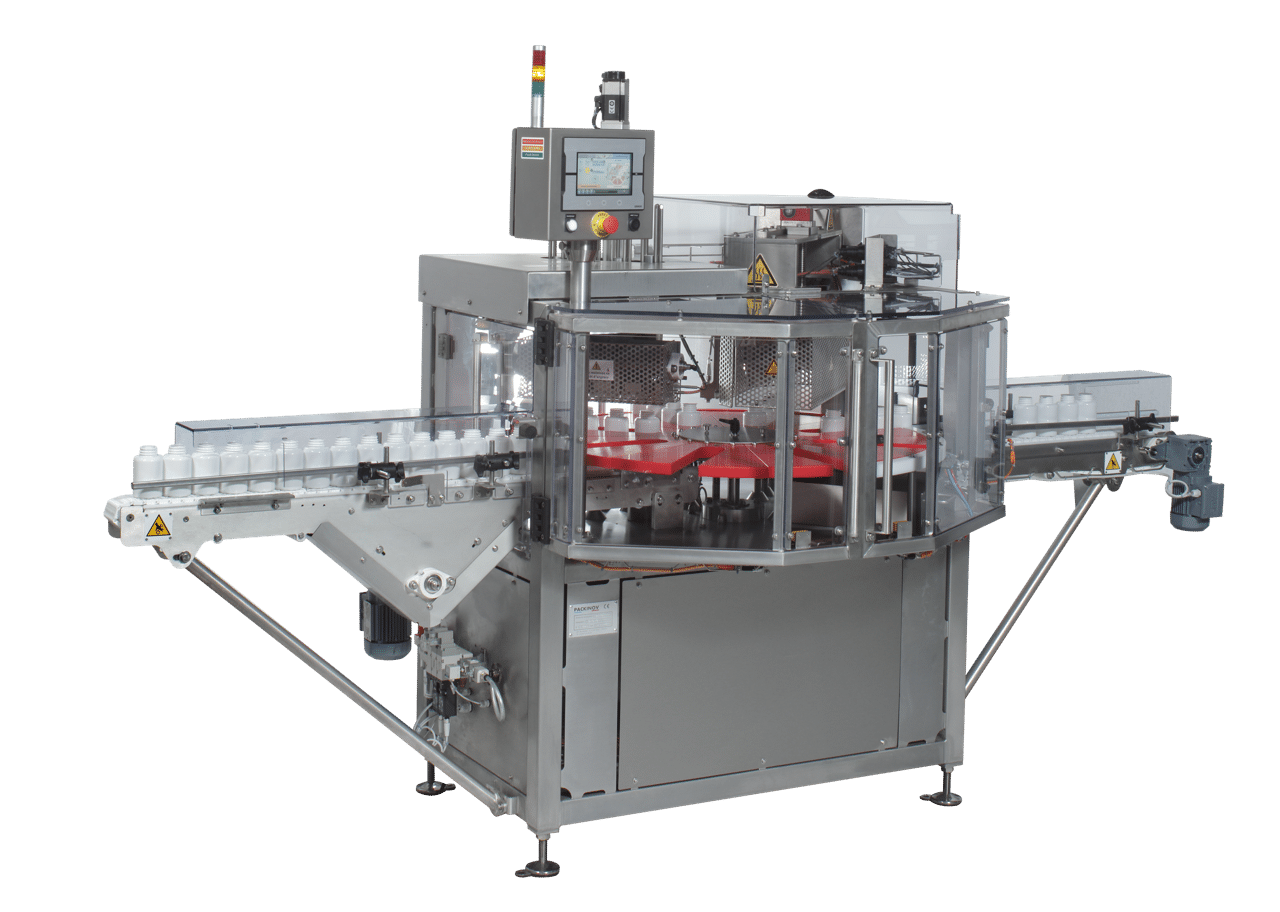

PACKINOV packaging machines and lines are essential to theThe cosmetics industryThese are an important part of the production process. These rotary or linear packaging machines are very efficient, flexible and easy to use for multi-format packaging adapted to the specific needs of each product and each container.

Whether it's solid, liquid or pasty products, creams, shampoos, oils, capsules, etc. The PACKINOV packaging solutions in the broadest sense, i.e. linear machines, rotary machines but also lids and associated services will provide reliable, local and high-quality solutions to all your needs. cosmetics industries looking for automated packaging.

The PACKINOV packaging machines comply with strict regulatory hygiene standards, while at the same time guaranteeing extremely precise and consistent dosing to save on raw materials and optimise profitability.

YOUR PRODUCTS to be packaged

Shampoo

Liquid soap

BODY MILK

lotion

oil

fragrance

cologne

powder

capsule

bath salts

scrub

food supplements

styling gel

skincare cream

exfoliating care

wax

balm

PACKAGING NEEDS in the cosmetics industry

- reliability

The PACKINOV packaging lines and rotary packaging machines for the cosmetics industry are of a great reliability for flawless production.

The performance of dosers ensures perfect dosing precision and consistency, for high production quality.

- productivity

High performance, PACKINOV packaging lines and machines for the cosmetics industry achieve very high speeds on a single track or on several tracks.

- scalable and modular

Made-to-measure in our design office in Francepackaging lines and machines for the cosmetics industry are designed, in conjunction with the customer, to be scalable and modular to adapt easily to changes in your production.

- simplicity

Simple to use, packaging machines for the cosmetics industry were studied to facilitate production, manage recipes directly from the control console and set the formats to automatic.

All our packaging machines are equipped with a easy to clean.

- hygiene and ergonomics

Our rotary machines and packaging lines for the cosmetics industry are designed to meet your specifications and your layout plan. custom-designed and developed for optimum ergonomics and hygiene.

The components in contact with your products are designed according to the recommendations of EHEDG.

ROTARY AND LINEAR

- A wide range of linear and rotary machines with different performance levels to meet your needs

- Made in France 100%

- Suitable for solid, unstackable or non-stackable containers, from the smallest to the largest

- Optimised ergonomics to reduce RSI

- Easy to clean

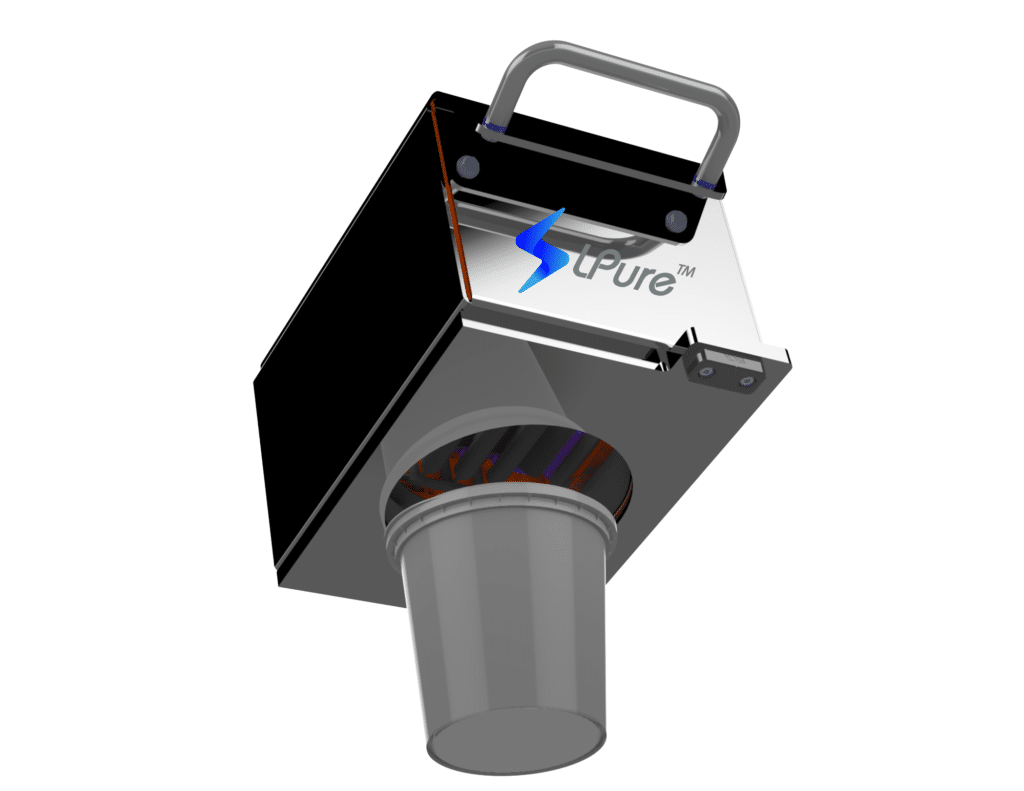

- LPure® pulsed light decontamination module

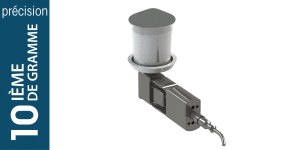

- 5-in-1 weighing control module for perfect dosing accuracy

- Tailor-made design, numerous optional modules adapted to your needs

- After-sales service provided by our teams in France

RMD Eco - Jam dispenser - 2020

RMD Eco - Jam dispenser - 2020

RMD Eco - Jam dispenser - 2020

Weighing control module

TH500 heat sealer

machines as well as lids and jars

- All our recommendations on a wide range of plastic, glass and cardboard pots

- Range of plain, custom and made-to-measure lids and heat-sealable films

- Tailor-made preventive and corrective maintenance contracts

- Numerous lid references in stock, safety stock possible

- A Design Office team at your service to structure your CDC

- Delivery anywhere in the world, to your production site

our in-house test laboratory

PACKINOV has its own production site in France, a quality testing laboratory.

La pot ⇔ lid compatibility can be tested therewhatever your container and its material, to ensure that perfect sealing, hold and peelability of the liner in your heat-sealing and production conditions.

Give us your pots and we'll carry out compatibility tests in our in-house laboratory!

Manufacture

100% French

OUR CONDITIONING MACHINES

For over 25 years, PACKINOV is a major player in the market packaging machines for the cosmetics industry.

The brand stands out for its closeness to customers and the outstanding quality of its linear and rotary packaging machines. PACKINOV offers a complete range of packaging solutions, adapted to each product, container, process and speed.

Based in Ain, France, the company has a design office, a production site and an after-sales service which enables every customer in the cosmetics industry to benefit from high-quality support to optimise and secure their production.

PACKINOV is the benchmark for packaging and filling machines for the cosmetics industry. The brand not only offers linear and rotary machines, as well as customised or diamond-tipped seals and associated services to meet the packaging needs of all its prospective and existing customers in the cosmetics market.

PACKINOV packaging machines meet strict regulatory standards while guaranteeing superior quality for all products. Visit linear and rotary packaging machines are flexible and can be adapted to the specific needs of each cosmetics industry, for each recipe and each container.

Thanks to its expertise in the field of linear and rotary packaging machines, PACKINOV is the partner of choice for the cosmetics industry looking to improve the reliability of their packaging processes, with the guarantee of a high quality product. 100% machine made in France.

From packaging machines linear or rotary, combining perfect precision and consistency of dosage for reliable production in cosmetics industry.

PACKINOV packaging machines also mean :

all our after-sales parts

in stock in France!

Internal after-sales service

with a dedicated team

rotary presses

or linear

Adapted

cosmetic containers

the cosmetics industry

After-sales services

PACKINOV's after-sales service is at your side to maintain, repair and upgrade your machine, filler or dispenser.

scalable and modular

PACKINOV will support you throughout the life of your machine and advise you as your production evolves.

Modifications will be carefully studied, proposed to you and then fully handled by our in-house teams, who are fully conversant with the technologies used on PACKINOV machines.

MADE-TO-MEASURE DESIGN

Retain all the flexibility you need to tailor 100% production to meet your requirements and specifications.

Our machines are designed by our in-house design office in France, in close collaboration with your teams.

Maintenance

PACKINOV's teams carry out annual maintenance on your machine and replace wearing parts to ensure that your filling machine operates at optimum efficiency and that your production continues uninterrupted.

100% French design and manufacture

All our semi-automatic and automatic machines are designed and manufactured in France by our in-house Design Office, at our production site in Beynost in the Ain department, in the heart of the Auvergne-Rhône-Alpes region. More than just a sales argument, at PACKINOV, 100% French manufacturing is a reality and almost an obsession!

And our objectives are clear: to reach 100% of PACKINOV subcontracting partners in France, so that we can play an active role in the national revival and momentum.

Today, our results are already very positive, with over 98% from our partners based in France, including 73% in the Auvergne Rhône Alpes region and 19% in the Ain. And the others are all European!

They trust us